With the rapid development of IDC data centers, the energy consumption problem in computer rooms is becoming increasingly severe, and the cooling system in computer rooms, as a major consumer of energy, has become a focus of attention. How to improve the utilization rate of cooling capacity and reduce the frequency of air conditioning use has also begun to be explored in depth. Interman has accumulated years of experience in data center refrigeration, combined with current trends and demands for energy conservation, emission reduction, and high heat density in data centers, to introduce innovative cold pool components. The cold pool can effectively improve the utilization efficiency of cold air in the cold channel of the computer room, improve the efficiency of cabinet air intake, prevent mixing of cold and hot air, and ultimately improve the energy efficiency of the computer room and reduce the PUE value.

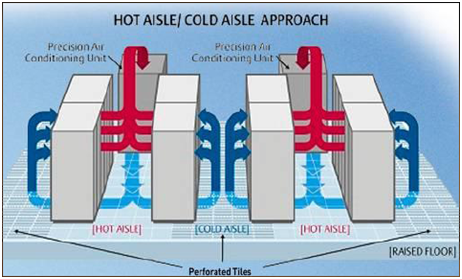

Figure 1: Traditional Cold and Hot Channel Separation Design

At present, the layout of data center cabinets mostly adopts a separation design of cold and hot channels, as shown in Figure 1. The advantage of this design is that it roughly distinguishes between hot and cold air, and has a better cooling effect than the more backward design of alternating cold and hot channels. However, due to the incomplete closure of the hot and cold channels, the cold and hot air will still mix extensively at the end or top of the cabinet column, which can lead to two problems: an increase in the inlet air temperature of the cabinet and a decrease in the return air temperature of the air conditioner. An increase in the inlet air temperature of the cabinet will result in a waste of air conditioning cooling capacity, affecting the heat dissipation of the cabinet and affecting the heat dissipation of the cabinet; Low return air temperature of air conditioning will lead to a decrease in air conditioning efficiency.

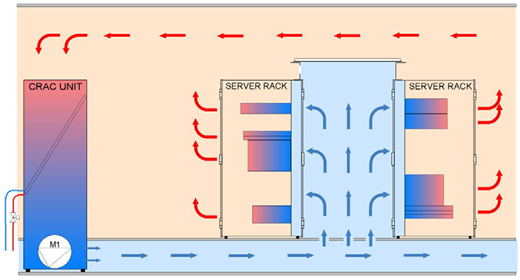

The simple and effective way to solve these two problems is to use a cold pool solution, as shown in Figures 2 and 3.

Figure 2 Schematic diagram of air flow organization in the cold pool

|

|

|

|

Figure 3 ETMAN Micromodule Renderings

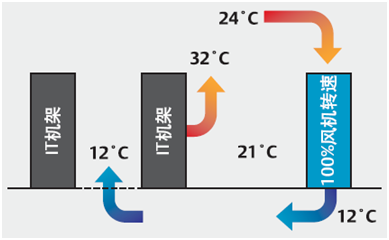

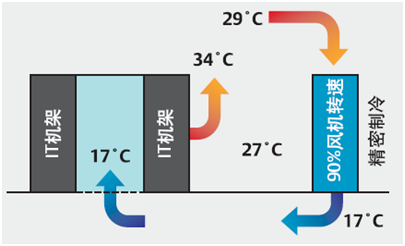

As shown in Figures 4 and 5. Due to the lack of any treatment for the cold (hot) channels in traditional computer room cabinets, the air conditioning supply temperature is about 12 ℃ -14 ℃, the return air temperature is about 22 ℃ -24 ℃, and the temperature difference is about 10 ℃ -12 ℃; After using a cold channel closure, the cold air is enclosed in a "cold pool". At this time, the path of the cold air entering the hot channel is through server heat exchange and discharged from the back of the cabinet, thus greatly improving the utilization efficiency of the cold air. At the same time, there is no mixing of cold air in the return air path, which increases the temperature of the air conditioning return air and thus improves the efficiency of the air conditioning system. The supply air temperature of the cold pool system can be increased to 17 ℃ -20 ℃, and the return air temperature can be increased to 28 ℃ -30 ℃.

Figure 4 Temperature schematic of traditional unclosed channels

Figure 5 Schematic diagram of cold pool temperature

Conservatively estimated, the cold pool can provide customers with a comprehensive energy saving rate of at least 4% compared to unclosed channels. If calculated based on a 1000KW load and an electricity fee of 0.75 yuan/kWh, the data center would be 1000KW/3 * 24 * 365 * 0.75=219000 yuan. So the cold pool can bring an annual electricity bill of 87600 yuan to save energy, equivalent to reducing 91 tons of carbon emissions. And the product cost recovery period shall not exceed 3 years.

The ETMAN micro module components have the following characteristics:

1. Standardization

Standard cold pool products generally consist of the following components:

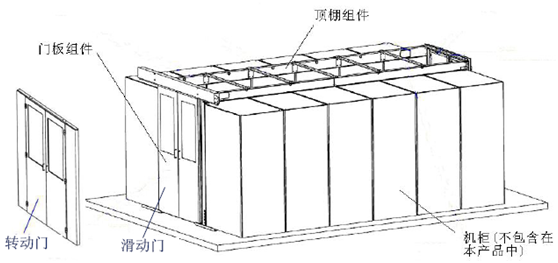

Figure 7 ETMAN Micromodule Product Composition

Door panel components: including front and rear doors (optional rotating doors (with door closer, maximum opening 180 °, 120 ° to remain fixed, 100 ° to automatically close), sliding doors (manual, automatic), doors can be equipped with toughened glass windows), installation components. (Mandatory)

|

|

Figure 8 Example of Door Panel Components

Ceiling components: including supporting sheet metal parts and transparent organic glass panels. (Mandatory)

Figure 9 Example of ceiling components

2. Modularization

The cold pool product is a specialized cold pool product for computer rooms launched by Inteman based on standardized design ideas. All components such as ceiling installation accessories, ceiling organic glass panels, front and rear doors, etc. are designed according to modular standards, making them easy to install, maintain, and replace. All accessories are connected with screws, which can achieve rapid deployment. As shown in the figure

|

|

Figure 10 Standardized Installation Process

3. Beautiful and elegant

The color of the Inteman cold pool components is black, with orange pattern spray coating, which can effectively reduce the discomfort caused by light reflection. The ceiling is made of organic glass panels with certain flame retardancy, with a light transmittance of over 80%. The working lighting in the channel adopts LED light strips, and a blue cold light source is installed between the two cabinets as the background light. The front and rear doors are high-quality double exterior glass doors, allowing for a clear view of the inside even without entering the aisle. All installation accessories have undergone strict factory inspection and deburring treatment, and the overall installation effect is beautiful and generous, as shown in the following figure:

Figure 11 Schematic diagram of installation effect

4. Customization

In addition to providing a variety of standard products, Inteman cold pool components can also be flexibly customized according to user needs.

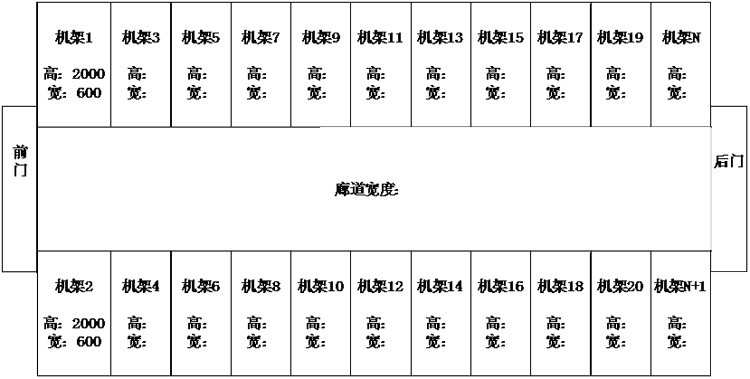

Figure 12 Customized Requirements for Cold Pool Products

As shown in the above figure, there are various types of options for the front and rear doors, and personalized customization can also be made according to different rack widths, heights, and corridor widths.

5. Intelligence

A temperature and humidity monitor is set in the cold channel, a temperature sensor is set in each cabinet, and a 12 inch touch screen is set at the entrance of the cold pool to view the microenvironment in the cold pool. Set a 3-inch number display screen on the top of each cabinet.

A high-definition camera is installed in the cold channel, and the cold channel door adopts an access control system. The channel door and ceiling can be linked with fire protection, and automatically opens when a fire alarm is triggered.